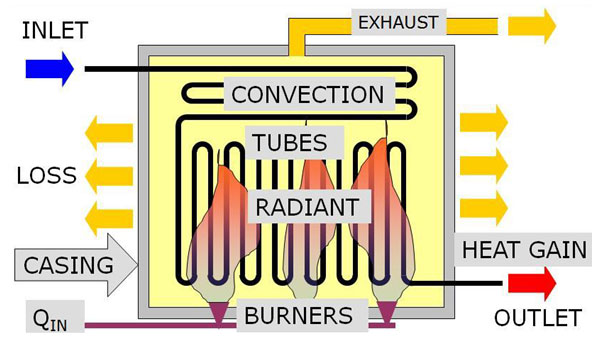

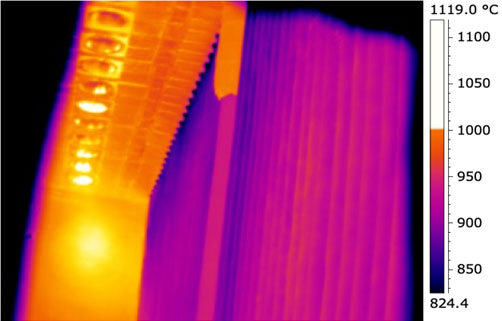

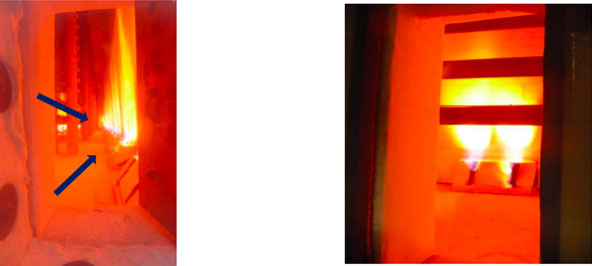

FURNACE THERMOGRAPHY

- Optimizing efficiency and performance in fired heaters

Specializing in thermography services for the petrochemical industry

Has developed state-of-the-art methodologies for diagnosing fired heaters

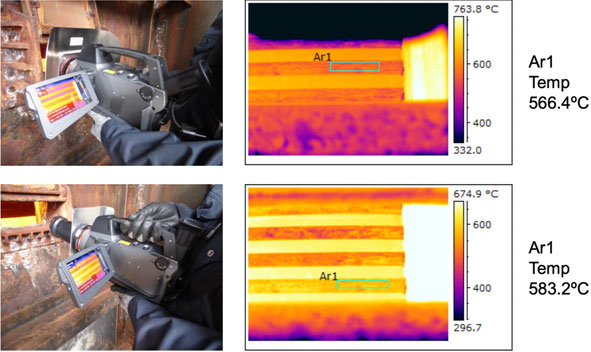

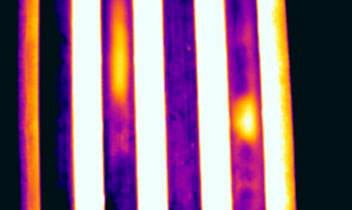

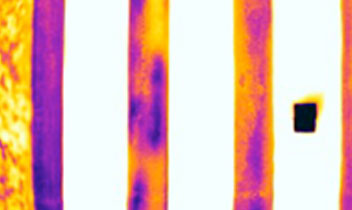

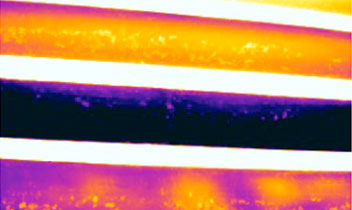

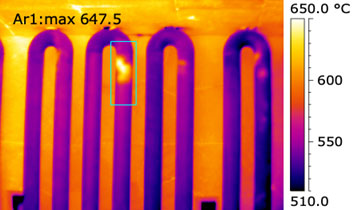

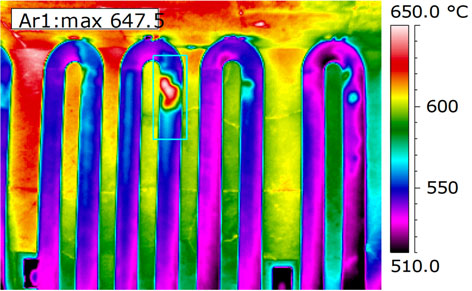

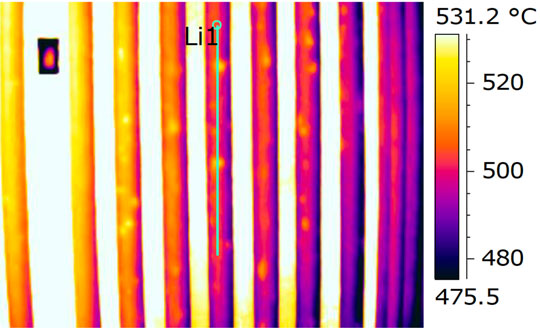

We measure accurate tube temperatures

- And we do much more than that. (We do not replace thermocouples; Thermocouples can never replace what we do; Thermocouples are active all the time, but can only give readings from single spots; Thermography gives information about the whole furnace interior)

- It is necessary to understand how the furnace works (Problems and their sources and patterns)

We have developed methods and knowledge to do a real diagnosis

Balanced heating (Making sure the heat is applied evenly in the whole furnace; prevents damage and lost production)

Baseline (Enables comparison with a known condition, improves analysis)

Look at the whole furnace, not just the tubes.

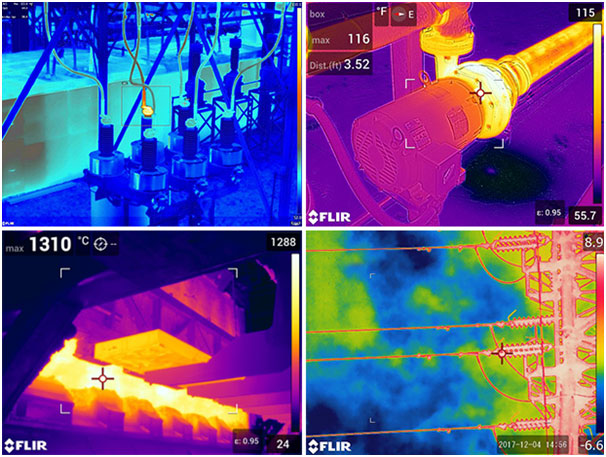

Electrical Thermography Inspection Services

- We provide electrical thermography services for Switch Gear, Service Disconnects, Transfer Switches, Bus Runs, Motor Control Centers, Breaker Panels, Starters, chillers and Roof top HVAC Equipment, VFD’s

- It makes it possible to conduct electrical thermal imaging surveys with no intrusion.

- Reduce Unscheduled downtime

It assures safety by detecting electrical problems in good time and avoiding fires caused by overloaded circuits or faulty wiring

Noise Survey

Noise survey is conducted in areas where noise exposure is likely to be hazardous. Noise level refers to the level of sound. A noise survey involves measuring noise level at selected locations throughout an entire plant or sections to identify noisy areas. This is usually done with a sound level meter (SLM).